Letoto la liqapi tsa hydraulic tse mahlakore a mabeli

-

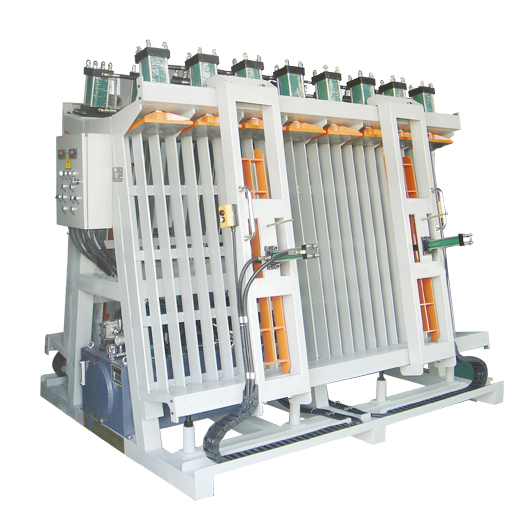

Letoto la likhatiso tsa hydraulic tse mahlakoreng a mabeli (Mofuta o tloaelehileng)

■ Mochine ona o amohela li-hydraulic principals tse khetholloang ka lebelo le tsitsitseng la ho sisinyeha, khatello e kholo 'me e ntse e hatella.

Re ka fana ka litšebeletso life?

Melao e Amoheletsoeng ea Thomello: FOB,CIF,EXW;

Chelete ea Tefo e Amoheletsoeng: USD, CNY;

Mofuta oa Tefo o Amoheletsoeng: T/T, Karete ea Mokoloto,L/C,

Senyesemane, Sechaena

■ Ho ea ka litlhaloso tse fapaneng tsa ho sebetsa (bolelele kapa botenya), khatello ea tsamaiso e ka fetoloa ho latela khatello e fapaneng e hlokahalang. 'Me ho na le tsamaiso ea khatello ea khatello, e tiisang khatello e sa khaotseng.

■ Taolo ea linomoro le ts'ebetso ea hotkey, e fokotsang ntlha ea batho le ho ntlafatsa boleng.

Ho na le mefuta e mengata e fapaneng ea li-hydraulic press. Kaofela ke mechini ea khatiso e sebetsang ka khatello ea metsi kapa ea hydraulic. Ho latela molao-motheo oa Pascal, mochine oa khatiso oa hydraulic o sebetsa hobane khatello e ntse e eketseha ho pholletsa le tsamaiso ea eona e koetsoeng, e sebelisa matla a lekanang ka har'a libaka tsohle tsa setshelo.

-

Mohaho oa fatše bakeng sa laminating

Mefuta ea Lisebelisoa tsa Hydraulic

Mechine ea khatiso ea Hydraulic e na le mefuta e mengata e fapaneng, e loketseng merero e itseng. Mona ke kakaretso ea lits'ebetso tse 'maloa:

Likhatiso tsa platen

Mochine oa khatiso oa C-frame ke mohlala oa mochine oa khatiso oa platen. Bohle ba sebelisa pheleu hammoho le ntho e tiileng, 'me ba na le bokaholimo bo entsoeng ka botsitso kelellong. Li ka sebelisoa ho etsa banka, ho taka, ho otlolla, ho phunya, ho kobeha, ho etsa le ho beha nako.

Lisebelisoa tsa vacuum le laminating

Likarete tsa ho reka ka mokitlane li entsoe ka mechine ena ea khatiso, e koahelang likarolo tse 'maloa tsa polasetiki. Mechine ena ea khatiso e ka boela ea sebetsa filimi.Mekhatlo ea ho hatisa

Hangata mechine ena ea khatiso e sebelisoa sebakeng sa mosebetsi oa likoloi le oa tšepe. Ba ka khaola le ho bopa lintho ka mokhoa o bitsoang deformation with die.

Likhatiso tsa ho fetisa

E sebelisoa hangata sebakeng sa sefofane le indastering ea bongaka, mechine ena ea khatiso e etsa hlobo le rabara ea setempe.Ho etsa mechine ea khatiso

Mechine ena ea khatiso e sebelisoa ka thata holim'a tšepe. -

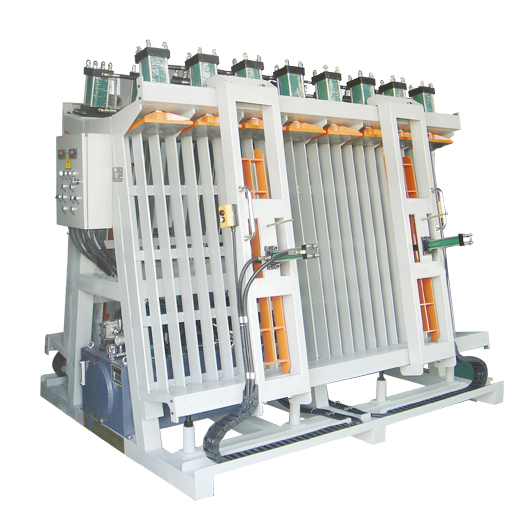

Letoto la likhatiso tsa hydraulic tse mahlakoreng a mabeli (Mofuta oa Karolo)

■ Mochine ona o amohela li-hydraulic principals tse khetholloang ka lebelo le tsitsitseng la ho sisinyeha, khatello e kholo 'me e ntse e hatella. Lishiti tse nang le matla a phahameng joalo ka bokaholimo ba mosebetsi le khatello e tsoang holimo le ka pele li ka thibela angle e kobehileng le ho etsa hore boto e khomarele ka botlalo. Lehlabathe le tlaase le tlhahiso e phahameng.

■ Ho ea ka litlhaloso tse fapaneng tsa ho sebetsa (bolelele kapa botenya), khatello ea tsamaiso e ka fetoloa ho latela khatello e fapaneng e hlokahalang. Hape ho na le tsamaiso ea khatello ea khatello, e netefatsang khatello e sa khaotseng.

■ Taolo ea linomoro le ts'ebetso ea hotkey, e fokotsang ntlha ea batho le ho ntlafatsa boleng

■ Mofuta oa likarolo, bakeng sa ts'ebetso e khuts'oane ea lehong, e fetohang haholoanyane le e phahameng haholo.

-

Letoto la likhatiso tsa hydraulic tse mahlakoreng a mabeli (Mofuta oa Karolo)

■ Mochine ona o amohela li-hydraulic principals tse khetholloang ka lebelo le tsitsitseng la ho sisinyeha, khatello e kholo 'me e ntse e hatella. Lishiti tse nang le matla a phahameng joalo ka bokaholimo ba mosebetsi le khatello e tsoang holimo le ka pele li ka thibela angle e kobehileng le ho etsa hore boto e khomarele ka botlalo. Lehlabathe le tlaase le tlhahiso e phahameng.

■ Ho ea ka litlhaloso tse fapaneng tsa ho sebetsa (bolelele kapa botenya), khatello ea tsamaiso e ka fetoloa ho latela khatello e fapaneng e hlokahalang. Hape ho na le tsamaiso ea khatello ea khatello, e netefatsang khatello e sa khaotseng.

■ Taolo ea linomoro le ts'ebetso ea hotkey, e fokotsang ntlha ea batho le ho ntlafatsa boleng

■ Mofuta oa likarolo, bakeng sa ts'ebetso e khuts'oane ea lehong, e fetohang haholoanyane le e phahameng haholo.

-

Mohaho oa fatše bakeng sa laminating

Mefuta ea Lisebelisoa tsa Hydraulic

Mechine ea khatiso ea Hydraulic e na le mefuta e mengata e fapaneng, e loketseng merero e itseng. Mona ke kakaretso ea lits'ebetso tse 'maloa:

Likhatiso tsa platen

Mochine oa khatiso oa C-frame ke mohlala oa mochine oa khatiso oa platen. Bohle ba sebelisa pheleu hammoho le ntho e tiileng, 'me ba na le bokaholimo bo entsoeng ka botsitso kelellong. Li ka sebelisoa ho etsa banka, ho taka, ho otlolla, ho phunya, ho kobeha, ho etsa le ho beha nako.

Lisebelisoa tsa vacuum le laminating

Likarete tsa ho reka ka mokitlane li entsoe ka mechine ena ea khatiso, e koahelang likarolo tse 'maloa tsa polasetiki. Mechine ena ea khatiso e ka boela ea sebetsa filimi.Mekhatlo ea ho hatisa

Hangata mechine ena ea khatiso e sebelisoa sebakeng sa mosebetsi oa likoloi le oa tšepe. Ba ka khaola le ho bopa lintho ka mokhoa o bitsoang deformation with die.

Likhatiso tsa ho fetisa

E sebelisoa hangata sebakeng sa sefofane le indastering ea bongaka, mechine ena ea khatiso e etsa hlobo le rabara ea setempe.Ho etsa mechine ea khatiso

Mechine ena ea khatiso e sebelisoa ka thata holim'a tšepe. -

Letoto la likhatiso tsa hydraulic tse mahlakoreng a mabeli (Mofuta o tloaelehileng)

■ Mochine ona o amohela li-hydraulic principals tse khetholloang ka lebelo le tsitsitseng la ho sisinyeha, khatello e kholo 'me e ntse e hatella.

Re ka fana ka litšebeletso life?

Melao e Amoheletsoeng ea Thomello: FOB,CIF,EXW;

Chelete ea Tefo e Amoheletsoeng: USD, CNY;

Mofuta oa Tefo o Amoheletsoeng: T/T, Karete ea Mokoloto,L/C,

Senyesemane, Sechaena

■ Ho ea ka litlhaloso tse fapaneng tsa ho sebetsa (bolelele kapa botenya), khatello ea tsamaiso e ka fetoloa ho latela khatello e fapaneng e hlokahalang. 'Me ho na le tsamaiso ea khatello ea khatello, e tiisang khatello e sa khaotseng.

■ Taolo ea linomoro le ts'ebetso ea hotkey, e fokotsang ntlha ea batho le ho ntlafatsa boleng.

Ho na le mefuta e mengata e fapaneng ea li-hydraulic press. Kaofela ke mechini ea khatiso e sebetsang ka khatello ea metsi kapa ea hydraulic. Ho latela molao-motheo oa Pascal, mochine oa khatiso oa hydraulic o sebetsa hobane khatello e ntse e eketseha ho pholletsa le tsamaiso ea eona e koetsoeng, e sebelisa matla a lekanang ka har'a libaka tsohle tsa setshelo.

Mohala: +86 18615357957

Mohala: +86 18615357957 E-mail: info@hhmg.cn

E-mail: info@hhmg.cn